-

Others Custom Products

Pressure Equipment Products

Turbine Auxiliary Equipment & Structures

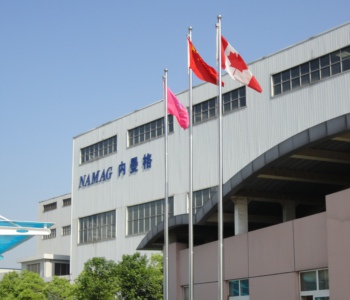

Zhejiang NAMAG Equipment

Manufacturing Co., Ltd.

Pressure vessels, prefabricated piping, reactors, heat exchangers, columns and process modules. - To be the most trusted partner and best supplier of Customers.

Turbine auxiliary equipment & structures including steel components for steam and gas turbines, intake & exhaust system for gas turbines, WHRU, etc. - Excellent sustainable EHS performance.

As a Tier-One supplier to several multi-national Corporation and Engineering Company, we are committed to continuous improvement of quality and deep understanding of different standards. - Quality is our Reason for Existence.

Zhejiang NAMAG Equipment Manufacturing Co., Ltd. established in 1997, is a Wholly Foreign-Owned Enterprise [WFOE] located in China and solely owned subsidiary of Whiting Equipment Canada, Inc.; affiliated with Whiting Corporation and sister company Swenson Technology, Inc., who locates in Monee, Chicago, USA, for over 130 years enjoy an excellent world-wide reputation.

NAMAG employs advanced design capabilities, is equipped with modern manufacturing facilities and a full range of in-house test equipment; the core group of administration, engineering and production personnel has received training in North America, which allow us to provide our Customers with globally accepted, quality products and services, manufactured in China.

Over the years we use North American technology but manufactures in China to give our Customers the competitive edge in quality, delivery and price. NAMAG’s diversified fabrication capacity is focused on three areas:

I. Pressure equipment

We design individually to customer requirements, and manufacture pressure vessel, prefabricated piping & piping spool, reactors & heat exchanger, columns, etc. in accordance with the following standards and codes:

· ASME Boiler and Pressure Vessel Code, Section VIII, Div.1 – (U Stamp (U-4), U2 Stamp, S Stamp, PP Stamp, National Board-NB

Stamp, R Stamp)

· China Code GB150 and GB151 for Level I, II and III Pressure Vessel (CS Stamp, SELO License certificate of pressure vessel design

and manufacturing)

· Pressure Equipment Directive 2014/68/EU (PED) for the European market– (CE Mark, Module H)

In addition, we could supply the pressure vessel to meet the other international codes and local requirements, for example, GOST Certificate (CU-TR) for Russia market, KGS Certificate for Korean market, CRN Registration for Canadian market, MOM Certification for Singapore market and AS Registration for Australian market, etc.

II. Turbine auxiliary equipment and structures

We can build to prints according to the customer’s specifications, including steel components for steam and gas turbines, intake & exhaust system for gas turbines and custom steel structure fabrication.

Through the collaboration with the global partners, we also provide the build-to-specification service/solution according to the customer’s data sheet and technical requirement. Our global partners have extensive experience of dimensioning, designing and manufacturing different system solutions in all environments, especially offer customers a large scope of the following supplies with whole range of know-how, competencies and capacities.

· Air Intake Systems

· Noise Enclosures & Ventilation

· Exhaust Systems

· Silencers

Meanwhile our engineers can design based on the technical requirement, such as prefabricated piping & ducts, all types of steel support structures, steel mezzanine platforms, skids, and other custom formed metal parts.

III. Other custom products

· Swenson chemical process equipment, including evaporator, crystallizer and dryers, etc. manufactured of both ferrous and non-ferrous

materials, a world leader in evaporation, crystallization and drying process for the chemical industry.

· Whiting metallurgical equipment, including electric arc furnaces, electro-fusion furnaces and refining vessels, etc.

· Process modules & skids fabrication, including detailed design, material purchasing, fabrication, assembly, painting, insulation, heat

tracing, electrical and instrumentation.

A Tier-One supplier to several multi-national OEMs, NAMAG provides special products and services for various fields, including chemical, petrochemical, energy, oil & gas, air separation, environmental protection, metallurgy, etc. Most of our products are exported to six continents and Oceania.

ISO 9001:2015, ISO 14001:2015 & OHSAS 18001:2007 registered, NAMAG maintains an overriding commitment to the environment, safety and quality, and the development and well being of our employees.

General Manager, Jerry Li, and his staff warmly invite Customers from home and abroad to visit our facilities in Tongxiang, Zhejiang Province, approximately 38 minutes from Shanghai.

Products & Services

All Rights Reserved. ©1997-2018 Zhejiang NAMAG Equipment Manufacturing Co., Ltd. 浙ICP备05061739号