Pressure vessels, prefabricated piping, reactors, heat exchangers, columns and process modules. - To be the most trusted partner and best supplier of Customers.

Turbine auxiliary equipment & structures including steel components for steam and gas turbines, intake & exhaust system for gas turbines, WHRU, etc. - Excellent sustainable EHS performance.

As a Tier-One supplier to several multi-national Corporation and Engineering Company, we are committed to continuous improvement of quality and deep understanding of different standards. - Quality is our Reason for Existence.

-

Others Custom Products

Pressure Equipment Products

Turbine Auxiliary Equipment & Structures

Zhejiang NAMAG Equipment

Manufacturing Co., Ltd.

Static Equipment Engineering

Engineering design is a process that consists of a series of continuing steps that leads to a complete solution to a problem. The solution may involve designing a product or a whole project to accomplish a certain task.

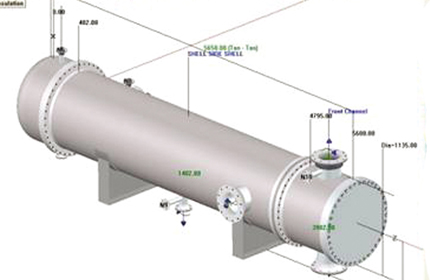

NAMAG has an in-house engineering division (R&D, Research & Development Division) dedicated to critical process equipment. Our professional designing engineers can prepare the most cost-effective design solution based on client special job requirements & applicable codes and turn client specifications into sophisticated equipment designs. We undertake special designs like Finite Element Analysis (FEA), stress analysis, fracture mechanics analysis, load analysis, etc. for special process requirements.

NAMAG expertise on Pressure Equipment’s engineering and with our international experience gained in more than 15 years of design and fabrication, we provide best solutions at the right cost and support process engineering companies in optimizing and customizing designs for chemical, petrochemical, air separation, etc. We also specialize in high-pressure applications and extreme service conditions of Highly Sour Services (HIC, SSC and SOHIC) and all other sever/lethal service.

Our production for Onshore and Offshore applications is in accordance with the main international Design Codes such as:

· ASME VIII Div.1

· ASME VIII Div.2

· ASME B31.3

· ASME B31.4

· ASME B31.8

· GB150, Pressure Vessels (China)

· GB151, Tubular Heat Exchangers (China)

· PED 2014/68/EU, (Europe)

· EN13445

· TEMA, Tube Heat Exchangers (USA)

· TSG, Supervision Regulations of Safety Technology for Pressure Vessels (China)

Our technical department is equipped with world-renowned software like Codeware Compress (ASME Code calculation), SW6 (China GB code calculation), Autodesk CAD, Autodesk Inventor (3D Models), UG, HTRI and FEA utilities to validate the designs.

Armed with a team of highly skilled engineers, a dynamic work force backed by necessary equipment and tools, we are geared to offer excellent products and technical service to global customers.

Other Equipment Engineering

Through the collaboration with the global partners, we also provide the build-to-specification service/solution according to the customer’s data sheet and technical requirement. Our global partners have extensive experience of dimensioning, designing and manufacturing different system solutions in all environments, especially offer customers a large scope of the gas turbine auxiliary equipment supplies with whole range of know-how, competencies and capacities.

Meanwhile our engineers can design based on the technical requirement or 3D product models, such as prefabricated piping & ducts, all types of steel support structures, steel mezzanine platforms, skids, and other custom formed metal parts.

Products & Services

All Rights Reserved. ©1997-2018 Zhejiang NAMAG Equipment Manufacturing Co., Ltd. 浙ICP备05061739号