Pressure vessels, prefabricated piping, reactors, heat exchangers, columns and process modules. - To be the most trusted partner and best supplier of Customers.

Turbine auxiliary equipment & structures including steel components for steam and gas turbines, intake & exhaust system for gas turbines, WHRU, etc. - Excellent sustainable EHS performance.

As a Tier-One supplier to several multi-national Corporation and Engineering Company, we are committed to continuous improvement of quality and deep understanding of different standards. - Quality is our Reason for Existence.

-

Others Custom Products

Pressure Equipment Products

Turbine Auxiliary Equipment & Structures

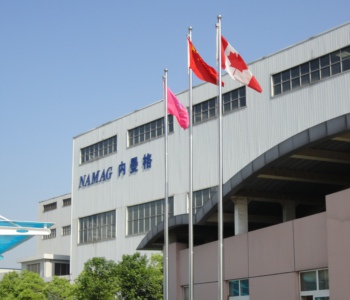

Zhejiang NAMAG Equipment

Manufacturing Co., Ltd.

Namag can deeply understand your needs to effectively manage risk. Combining Namag’s internal inspection practices with external inspection, be it your own inspector or a third-party firm, is the best way to ensure that you get the quality you expect, every time.

Open Shop Policy

Your inspectors are welcome at Namag at any point during the fabrication process. Some clients do spot checks while others prefer to have inspectors in our shop throughout the entire project.

Third Party Inspection Firms

Namag has worked with all major third-party inspection firms and is competent at coordinating inspections efficiently, including Moody, Intertek, BV, ABS, TUV, Hartford Steam Boiler Inspection and Insurance Co. (HSB), etc.

Inspection and Test Plan

The heart of a successful inspection process is the development of the Inspection and Test Plan or ITP. Before any work begins, we’ll work collaboratively with your technical staff, inspector, and project manager to ensure that all critical items are identified and that everyone is comfortable with inspection regime and methods.

Planning Simplicity

An additional advantage of working with Namag is that planning inspections is simple because most major processes take place at one facility. Some of these include: cutting, partial machining, forming, welding, leak test (including hydro test, air/oxygen/argon/nitrogen test), blasting for carbon steel and stainless steel, painting and all forms of NDT.

We have some qualified suppliers with solid & good partner relationships, mainly for high-requirement machining, HDG (hot dip galvanizing) and PWHT (post weld heat treatment), who are audited by our main customers including GE, Siemens, Alstom, etc.

All Rights Reserved. ©1997-2018 Zhejiang NAMAG Equipment Manufacturing Co., Ltd. 浙ICP备05061739号

Products & Services