-

Others Custom Products

Pressure Equipment Products

Turbine Auxiliary Equipment & Structures

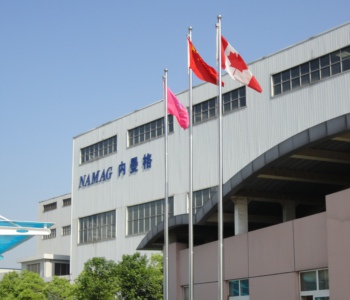

Zhejiang NAMAG Equipment

Manufacturing Co., Ltd.

Pressure vessels, prefabricated piping, reactors, heat exchangers, columns and process modules. - To be the most trusted partner and best supplier of Customers.

Turbine auxiliary equipment & structures including steel components for steam and gas turbines, intake & exhaust system for gas turbines, WHRU, etc. - Excellent sustainable EHS performance.

As a Tier-One supplier to several multi-national Corporation and Engineering Company, we are committed to continuous improvement of quality and deep understanding of different standards. - Quality is our Reason for Existence.

Chemical Process Engineer

Job Description

· Responsible for developing chemical equipment and improving old products’ quality.

· Setting the process condition, optimizing the production process and creating corresponding files.

· Responsible for controlling chemical equipment in production and analyzing exceptional technical problems

· Responsible for introducing and supervising the application of new techniques to the new products

· Responsible for improving process techniques and introducing the new technology.

· Responsible for training and guiding the relevant staffs in the workshop.

Job Requirement:

· Bachelor or above. Chemistry, chemical engineering machinery, macromolecule is preferred

· 2 years or above in chemical production or with technological working experience, especially with chemical technology management

experience

· Familiar with operation of laboratory equipment, better understand and operate chemical facilities and vessels, with solid theory and

abundant experimental experience are given priority to consider.

· Effectively using AUTO CAD drawing software with strong communication and analytical, creative, experimental designing abilities.

· Strong initiative and dedication to work, hard-working spirit.

· This staff will be sent to North America to train for 1-2 year if selected.

Planner and Production Capacity Arranger

Job description:

· Drawing up production plan: Responsible for formulating and arranging working schedule for main products and other accessories

regarding to monthly, seasonal, yearly plan and other requirement from the company.

· Preparing production: inspect, guide, coordinate all relevant depts. to make preparation for production; understand the periodical gap

between actual production and raw material supply , arrange facilities and staff wisely; Supervise raw material, equipment, energy supply

and transportation condition in the factory to raise the flexibility of on-site production, to minimize the side effect on the actual production

arising from accidents.

· Controlling the production process: check ratio of raw material, semi-products to the finished products; find out problems and solve them

immediately with proper solutions.

· Analyzing production data: Investigated data related to the daily and night shift or monthly on-line plan, other production data. (Such as

record the reasons lead to labor hours cut, machine damage, production capacity fluctuation)

· Daily management on the production : Examine and solve irregular problems on duty;Feedback to the sales and marketing depts. about

the production status; responsible for delivering messages from the higher lever to the lower lever, reporting to the higher lever about the

situation in the workshop

Requirement:

· Bachelor degree, major of science and engineer, familiar with Office, AUTOCAD, PROJECT software etc;

· Loyal and dedicate to the company with hard-working spirit.

Painting Engineer

Job description

· Drafting, checking、revising the process file and involve in process design.

· Involving in painting technology improvement

· Participating in process inspection and work absence check

· Organizing, designing, implementing the new products painting

· Responsible for stipulating painting and work hour consumption quota.

Requirement

· Bachelor degree, chemical engineering or related major

· High level of English listening, speaking, reading, writing.

· With NACE 2nd level certificate.

· Familiar with metal structure painting technology

· Familiar with frequent-used paints function and construction technology

· With 3-year industry related working experience.

· Good communication skills and team-work spirit.

Welding Engineer

Job description

· Responsible for evaluating new products welding process, drawing up PQR and WPS

· Working in the factory and familiarize the welding quality; Direct, inspect welding process and solve technological problems arising, give

technological support to the whole process.

· Ensuring that the process agrees with drawing, standards and actual welding requirement. Discover and solve problems with proper

solutions

· Appling special welding material in the experimenting the new model.

· Responsible for training, examining the welder to help them get the qualified certificates

· Drafting and implementing the welding technology rules, regulation, standards.

· Assisting customers’ inspection work

Requirement

· Male, bachelor degree, welding or related major

· One year in machinery or related industry, hard-working quality, strong initiative.

· Effectively use CAD drawing with English and computer knowledge.

Pressure Vessel Designing Auditors

Job description

· Auditors must pass the examination after the required training, and get the pressure vessel design and approving staff qualification with

corresponding level

· Involving in pressure vessel initiate design, mainly technological problem discussion.

· Assisting designer and examining staff in solving problems and immediately check the design to avoid reworking

· In charge of checking the design that whether the design draft corresponds with designing task. and reality, whether it is technological

advanced, economy reasonable, safety trustable.

· In charge of checking material for facilities structure to ensure raw material is correct, basic date and formula, calculating result is also

correct.

· Properly handling the opinions between the designer and auditors

· Taking the main responsibility of the correctness of technological problem and design

· Fully involving in grade estimation and record the design quality, write comments to design work complying to the rules.

Requirement

· with qualified D1/D2 pressure vessel certificate

· Junior engineer

· More than 6-year working experience, those who can provide related working proof are preferred.

Products & Services

All Rights Reserved. ©1997-2018 Zhejiang NAMAG Equipment Manufacturing Co., Ltd. 浙ICP备05061739号