Pressure vessels, prefabricated piping, reactors, heat exchangers, columns and process modules. - To be the most trusted partner and best supplier of Customers.

Turbine auxiliary equipment & structures including steel components for steam and gas turbines, intake & exhaust system for gas turbines, WHRU, etc. - Excellent sustainable EHS performance.

As a Tier-One supplier to several multi-national Corporation and Engineering Company, we are committed to continuous improvement of quality and deep understanding of different standards. - Quality is our Reason for Existence.

-

Others Custom Products

Pressure Equipment Products

Turbine Auxiliary Equipment & Structures

Zhejiang NAMAG Equipment

Manufacturing Co., Ltd.

Materials are a key factor in product compliance. All design codes have “approved” materials listed or referenced, including pressure equipment, machinery, other equipment, etc. Thus, the basis for design is always a system which includes design formulas, materials, as well as manufacturing and testing requirements.

NAMAG provides the adaptability to meet our customer’s specific welding and special requirements. With extensive experience and knowledgeable Manufacturing Engineers, we are considered as a valued supplier of important weldments with high requirements to numerous industries worldwide. We are qualified to perform different welding standards to a wide variety of material groups in accordance with ASME Code, European EN standards, Chinese GB standards, etc.

Materials Welded

These products are generally made in carbon steel, low alloy Steel (Cr-Mo), austenitic stainless steel, clad steel, duplex or duper duplex stainless steel, titanium, aluminum, nickel and Inconel alloy, etc, and Namag have the solid welding experience, especially in the special material Titanium, AL6XN, 904L, Inconel 625, Monel 400, etc.

Special Medium & Conditions

Namag has solid and rich experience in the following medium and conditions:

· Sour Medium Environment - NACE MR 0175 Metals for Sulfide Stress Cracking and Stress Corrosion Cracking Resistance in Sour Oilfield

Environments

· Hydrogen Induced Cracking (HIC) Test

· Sulfide Stress Cracking (SSC) Test

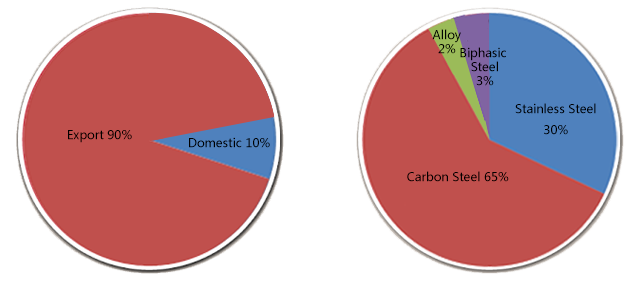

Export Ratio Classified by type

Materials Forms

Plate and Sheet

Tubes/Nozzles

Castings/Forges

Cladding

Beam/Profiles/Angle plates

Welding Processes

GTAW, Gas Tungsten Arc Welding

SMAW, Shielded Metal Arc Welding

GMAW, Gas Metal Arc Welding

FCAW, Flux Core Arc Welding

SAW, Submerged Arc Welding

PAW, Plasma Arc Welding

MIG, Metal Inert Gas (MIG) Welding

TIG, Tungsten Inert Gas (TIG) Welding

Industries

Agriculture

Chemical

Petrochemical

Desalination

Food

LNG

Mining

Oil and Gas

Pharmaceutical

Power Generation

Renewable Energy

Air Separation

Environment Protection

Products & Services

All Rights Reserved. ©1997-2018 Zhejiang NAMAG Equipment Manufacturing Co., Ltd. 浙ICP备05061739号