-

Others Custom Products

Pressure Equipment Products

Turbine Auxiliary Equipment & Structures

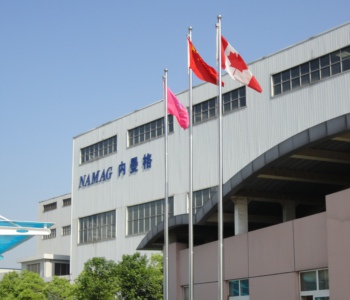

Zhejiang NAMAG Equipment

Manufacturing Co., Ltd.

Pressure vessels, prefabricated piping, reactors, heat exchangers, columns and process modules. - To be the most trusted partner and best supplier of Customers.

Turbine auxiliary equipment & structures including steel components for steam and gas turbines, intake & exhaust system for gas turbines, WHRU, etc. - Excellent sustainable EHS performance.

As a Tier-One supplier to several multi-national Corporation and Engineering Company, we are committed to continuous improvement of quality and deep understanding of different standards. - Quality is our Reason for Existence.

At Namag, we understand that tower, stripper column and vessel quality is critical to job performance. As an industry-leading vessel manufacturer for the oil & gas, petrochemical and other industries, our state-of-the-art quality control processes ensure operator safety and optimal quality of each piece of hand-crafted equipment.

Whatever the distillation or filtering requirement of the vessel, including batch or continuous operation, we can build a column to meet most applications. These columns can be built to a variety of sizes and can be furnished for atmospheric pressure or designed for internal and external pressure. All materials are available including carbon steel, low alloy Steel (Cr-Mo), austenitic stainless steel, clad steel, duplex or duper duplex stainless steel, alloy steel, etc. Besides, trays and packing mediums can be added as an option and can be factory installed prior to delivery.

The over-the-road transportation load dimensional limits in China normally restrict the size of our product to less than 6 meters in diameter and 40 meters in length, but we could transport the big vessels in the maximal diameter 8 meters by the canal river near our plant. In addition, with special permits or dockside for final assembly fabrication we have accommodated Customers with much larger ocean shipment sizes.

After years of engineering, manufacturing, and installing components and internals for large-scale, trayed towers, absorption towers and distillation columns, our professional engineers can provide the optical suggestion for the longevity and durability of each standard and custom design. Each of our custom column & tower vessel is fabricated, assembled, tested and guaranteed to conform to ASME Division 1, Section VIII standards (American Society of Mechanical Engineers) and customer’s specified requirements.

In the review of the customer’s project requirements, our engineering team and manufacturing team will provide the best collaboration, engineering and manufacturing services to customers, while providing the best delivery cycle in the industry on condition to quality guarantee.

We provide the fabrication service for the refining, oil & gas, waste treatment, chemical and other industries, and our customers mainly include the global corporations in the upstream, midstream and downstream markets who expect the best in engineering, design and manufacturing.

Products & Services

All Rights Reserved. ©1997-2018 Zhejiang NAMAG Equipment Manufacturing Co., Ltd. 浙ICP备05061739号

Products & Services