Pressure vessels, prefabricated piping, reactors, heat exchangers, columns and process modules. - To be the most trusted partner and best supplier of Customers.

Turbine auxiliary equipment & structures including steel components for steam and gas turbines, intake & exhaust system for gas turbines, WHRU, etc. - Excellent sustainable EHS performance.

As a Tier-One supplier to several multi-national Corporation and Engineering Company, we are committed to continuous improvement of quality and deep understanding of different standards. - Quality is our Reason for Existence.

-

Others Custom Products

Pressure Equipment Products

Turbine Auxiliary Equipment & Structures

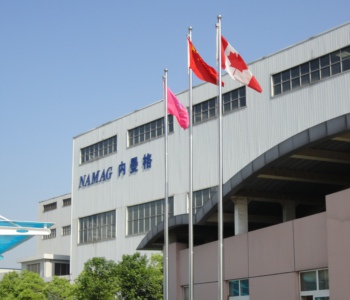

Zhejiang NAMAG Equipment

Manufacturing Co., Ltd.

NAMAG, based in Tongxiang, Zhejiang, China, specializes in the fabrication of pressure vessels, prefabricated piping, reactors & heat exchangers, columns, gas turbine auxiliary equipment, plate work and structural steel. We have maintained an outstanding reputation in this industry since 1997, yet the parent company’s history goes back more than a century.

Our facility is ASME Code Certified under Section VIII, Division 1 & 2, of the ASME Code to use U Stamp(U-4), U2 Stamp, S Stamp, PP Stamp, R stamp and NB Stamp. We also are registered with the National Board of Boiler and Pressure Vessel Inspectors of America.

Our facility incorporates more than 85,000 Sq. m lands, including 46,000 Sq. m of enclosed fabrication areas. There we have the additional protected areas for NDT, sand blasting and painting. In the shop production management, carbon steel and stainless steel are completely separated.

We invite you to visit and inspect our fabrication facility at any time. We value our client relationships and prove our worth through professionalism and superior workmanship. We are proud of our facility and personnel, and hope that you will be pleased with our capabilities and expertise after your visit.

Workshop Summary

No. 1 Shop, East Plant

· Land Area: approx. 23,000 sq. m;

· Shop area: approx.15,000 sq. m with three bays;

· Max. 16 m under crane hook;

· Double rails for cranes, and max. individual crane capacity: 75 tons

· Painting Room: 20m (L)×10m (W)

· Sandblasting Room: 15m (L)×7.5m (W) ×2

· Indoor warehouse: approx. 500 Sq. m

· Non-destructive testing, RT Room

No. 2 & No. 3 Shop, West Plant

· Land area: approx. 33,000 sq. m

· R & D Center, approx. 500 sq. m

· Training Center, approx. 300 Sq. m

· Science Lab, Physical analysis & Chemical analysis, approx. 150 Sq. m

· Indoor Warehouse, approx. 3,000 Sq. m

No. 2 Shop, West Plant

· Shop area: approx. 8,500 sq. m with three bays;

· Max. 11m under crane hook, max. individual crane capacity: 50 tons;

· This shop is only for Stainless Steel fabrications;

· Pickling & Passivation facilities.

· Sandblasting Room d for stainless steel product: 12m(L)×11.5m(W)

No. 3 Shop, West Plant

· Shop area: approx. 8,500 sq. m with three bays:

· Max. 11m under crane hook, max. individual crane capacity: 50 tons;

No. 4 Shop, Shengmao Plant

· Shop area: approx. 6,000 sq. m with two bays, 12 m under crane hook, Crane capacity:20 tons:

· This shop is for steel structure production;

No. 5 Shop, Lutou workshop

· Shop area: 8,000 sq. m with three bays, 7 m under crane hook, Crane capacity:20 tons

· 5,000 sq. m is used for storage.

Main Equipment & Facilities

All of our fabrication activities employ modern machines, facilities and well-trained employees.

NAMAG have solid manufacturing experience, and all work is monitored by our own Quality Control Department. This includes all pressure and structural welding, equipment assembly, insulation, sandblasting, pickling, Passivation, testing and painting.

Our workshops incorporate a wide range of steel processing equipment including:

√ Cutting machines: plasma, CNC oxygen, laser, shears;

√ Beveling machine;

√ Bending machines;

√ Rolling machines:

√ Machining equipment;

√ Welding equipment for manual, semiautomatic and automat welding: GMAW (Gas Metal Arc Welding), GTAW (Gas Tungsten Arc

Welding), SAW (Submerged Arc Welding), SMAW (Shielded Metal Arc Welding) and FCAW (Flux Core Arc Welding).

√ Tube expanding machine;

√ Sandblasting equipment;

√ Painting equipment: conventional and airless spray;

√ Test equipment: VT (Visual Test), RT (Radiography Test), UT (Ultrasonic Test), PT (Penetrate Test), MT (Magnetic Particle Test), leak

testing and coating inspection.

√ Max. Individual crane capacity: up to 75 tons.

Besides, we have qualified subcontractors with good business-cooperation relationship to assist us to complete some activities, such as electroplating, partial machining, heat treatment, etc.

We have made the commitment to our customers and employees to have the equipments and facility to produce the highest quality fabrication. We are constantly upgrading our industrial fabrication facility with state-of-the-art equipment to make this possible.

Products & Services

All Rights Reserved. ©1997-2018 Zhejiang NAMAG Equipment Manufacturing Co., Ltd. 浙ICP备05061739号