In recent years, the issue of global climate change has become increasingly prominent, and countries have strengthened carbon emission management and promoted green development. Under this trend, my country has also continued to increase its attention to carbon footprint management and introduced a series of relevant policies to encourage companies to establish carbon emission accounting, reporting and verification standards, and explore product life cycle carbon footprint management.

In order to fulfill the company's environmental responsibility and sustainable management awareness, we hired a third-party company to conduct in-depth investigations and studies on the company to help companies understand the carbon emissions of different links in the product life cycle. Based on this, we officially released the 2023 product carbon footprint evaluation report.

Product Carbon Footprint (PCF)

What is a Product Carbon Footprint?

A Product Carbon Footprint (PCF) is the sum of (cumulative, aggregate, total) greenhouse gas (GHG) emissions "produced or used" throughout the full life cycle (lifespan) of a good or service ("product"), including production, consumption and end-of-life treatment. It may include atmospheric carbon removal, if any, that is directly associated with producing, consuming the product and/or the end-of-life treatment of the product.

Carbon Inventory

Every PCF prepares a greenhouse gas (GHG) inventory (see: Carbon inventory), which is a complete account of all greenhouse gas (GHG) emissions and removals associated with the product. In some cases, a PCF may only cover emissions over a portion of a product's lifespan, e.g., 'cradle-to-gate' (which includes emissions from raw material extraction/cultivation up the point that a product leaves the reporting company's factor gate, i.e., immediately following final production), thus making it a partial lifecycle PCF; or a PCF may only include certain greenhouse gases, e.g., exclusively Carbon dioxide (CO2), excluding, for example, Methane or Nitrous oxide, if any, which may result in the PCF not being standard compliant. Refer to Product Standard. In some instances, if other greenhouse gases account for an insignificant fraction of the total carbon inventory, they can be excluded while the PCF remains standard-compliant.

Life Cycle Assessment v. Product Carbon Footprint

A Life Cycle Assessment (LCA) involves assessing some or all environmental impacts, typically, for all life cycle stages associated with a product; as such, an LCA typically includes a GHG inventory. The following are available and detailed in the sub-section, Unit of measure, below: Global warming potential (GWP) conversion factors for the 200+ greenhouse gases in life; and The Big Three greenhouse gases, namely, Carbon dioxide (CO2), Methane (CH4), and Nitrous oxide (N2O).

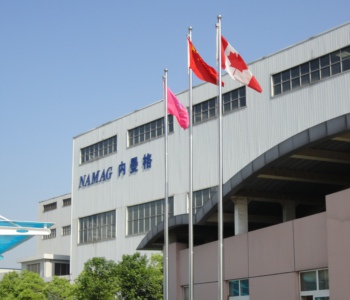

About NAMAG

Namag is a leading pressure equipment & gas turbine auxiliary equipment supplier located in China. We help Customers to meet construction schedules and control costs through the supply of world-class quality pressure vessels, prefabricated piping, reactor & heat exchangers, tower vessel & columns, turbine auxiliary equipment, structures, and process modules from China.

Zhejiang NAMAG Equipment Manufacturing Co., Ltd. established in 1997, is a Wholly Foreign-Owned Enterprise [WFOE] and solely owned subsidiary of Whiting Equipment Canada, Inc.; affiliated with Whiting Corporation and sister company Swenson Technology, Inc., who locates in Monee, Chicago, USA, for over 130 years enjoy an excellent world-wide reputation.

We provide the technical service for the chemical, petrochemical, oil & gas, energy, air separation, environment other industries, and our customers mainly include the global corporations in the upstream, midstream, and downstream markets who expect the best in engineering, design and manufacturing.

With resources and experience in the global projects, we are proud to partner with our customers to deliver experience, expertise, and unrelenting commitment to products & technical service.

For more information about the company and its products and services, please visit: www.namag.cn.

Contact Us

Charles ZHANG

Marketing Dept.

Phone: +86 573-88023680

E-mail: market@namag.cn